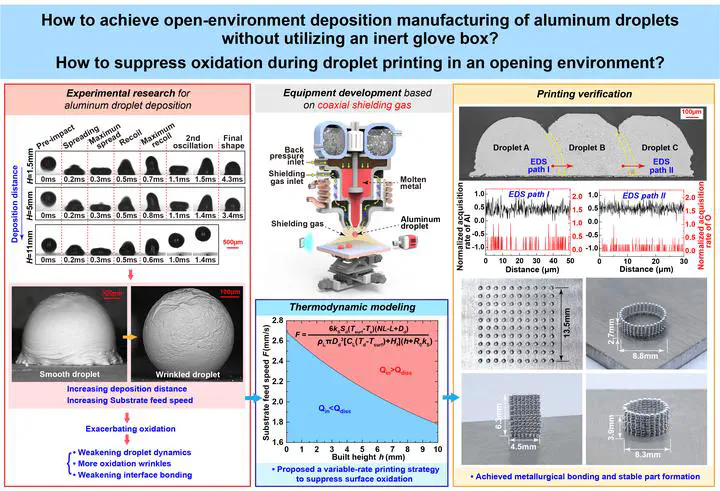

Uniform aluminum droplet deposition manufacturing in an open environment: Oxidation suppression and stable printing under coaxial shielding gas

Abstract

Employing opening shielding gas in metal micro-droplet deposition enables lightweight, real-time, eco-friendly manufacturing. However, aluminum alloys, highly sought-after for manufacturing, face challenges in equipment development and experimental research due to their high oxidation reactivity and thermal sensitivity. This study presents a novel approach that combines piezoelectric actuation with dynamic coaxial gas shielding. The method enables stable aluminum droplet printing with micron-level precision in an open environment. Through combined experiments and theoretical models, the impact of oxidation on droplet deposition dynamics, surface morphology, and formation quality was investigated. Results show that even a slight change in the deposition distance would cause significant variations in deposition and oxidation behavior. Increasing the deposition distance not only exacerbates droplet oxidation and dampens droplet oscillation, but also forms oxidation wrinkles on the droplet surface. A higher substrate feed speed also reduces the shielding gas effectiveness. This effect is particularly significant in multi-layer droplet pileup, where heat accumulation delays solidification and exacerbates oxidation in the upper-layer droplets. To address these challenges, a variable-speed printing strategy based on thermal management was proposed. This method suppresses droplet surface oxidation, enabling metallurgical bonding and stable part formation in open environments. This work provides both practical strategies and theoretical insights for oxidation control in high-temperature metal droplet printing under open-environment conditions.